nosferatux

New member

como veo el tema paradillo y ninguno enseñais vuestros avances, me he decidido a poner este post para que os riais un poco con mis desgracias

hoy aunque es sabado, me he levantado pronto y he decidido ponerme a jugar con las piezas del mecano que han llegado esta semana.

os pongo unas fotos de como va el proceso, para que las critiqueis todo lo que os apetezca.

las fotos malas como siempre :rofl::rofl:

el paciente segun llego a casa (poco se esperaba lo que le iba a suceder)

el sujeto despues de someterlo a la tortura por desmenbramiento (vamos como si hubiese atentado contra el rey)

como ni aun asi confesaba, tuve que someterlo a una tortura a base de chorro de arena

despues de chorrearlo un rato, al fin confeso, por lo que le pedi a un asiatico que me mandara algunos miembros para volver a dejarlo en estado de revista.

a partir de aqui le podeis ver como se va completando

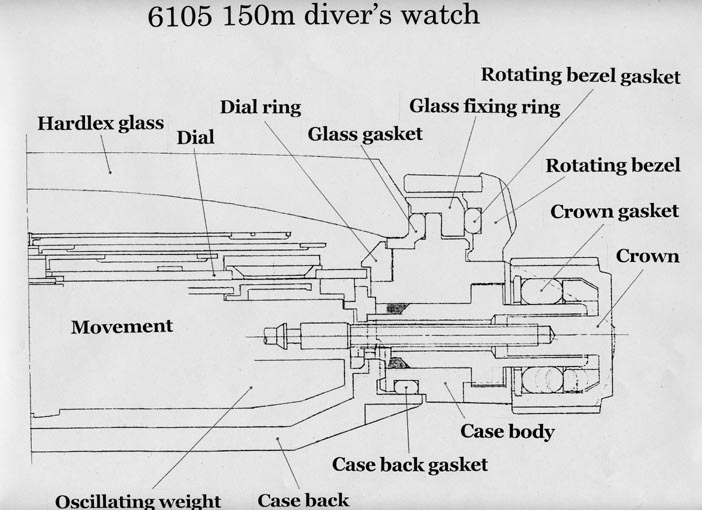

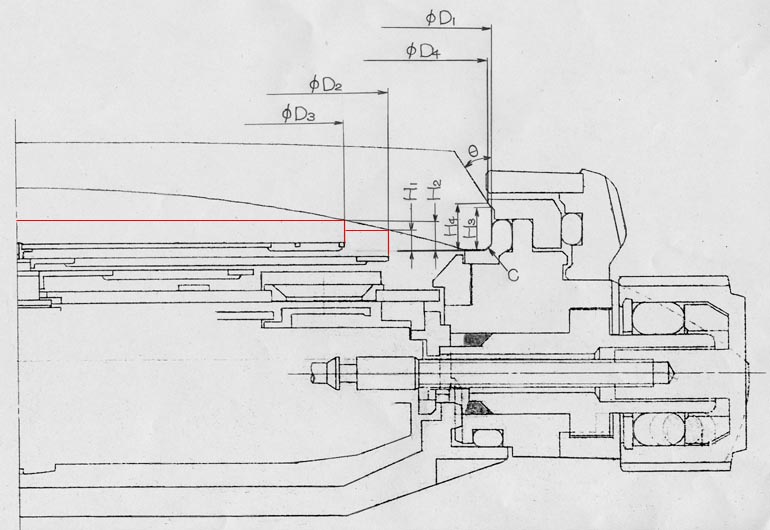

a pertir de aqui bienen los problemas. para cambiar el chapter ring, tuve que quitar el cristal, al quitar el cristal se me fastidio la goma y ademas no hay dios que vuelva a poner el aro que sujeta el cristal.

Helppppp donde puedo comprar la goma y quien tiene una prensa para ajustar el cristallllllllll :grrrrrr::grrrrrr:

hoy aunque es sabado, me he levantado pronto y he decidido ponerme a jugar con las piezas del mecano que han llegado esta semana.

os pongo unas fotos de como va el proceso, para que las critiqueis todo lo que os apetezca.

las fotos malas como siempre :rofl::rofl:

el paciente segun llego a casa (poco se esperaba lo que le iba a suceder)

el sujeto despues de someterlo a la tortura por desmenbramiento (vamos como si hubiese atentado contra el rey)

como ni aun asi confesaba, tuve que someterlo a una tortura a base de chorro de arena

despues de chorrearlo un rato, al fin confeso, por lo que le pedi a un asiatico que me mandara algunos miembros para volver a dejarlo en estado de revista.

a partir de aqui le podeis ver como se va completando

a pertir de aqui bienen los problemas. para cambiar el chapter ring, tuve que quitar el cristal, al quitar el cristal se me fastidio la goma y ademas no hay dios que vuelva a poner el aro que sujeta el cristal.

Helppppp donde puedo comprar la goma y quien tiene una prensa para ajustar el cristallllllllll :grrrrrr::grrrrrr: